Licensed Yacht BrokersSales and service of yachts and ships

Licensed Yacht BrokersSales and service of yachts and shipsBRIZO YACHTS - For Sale

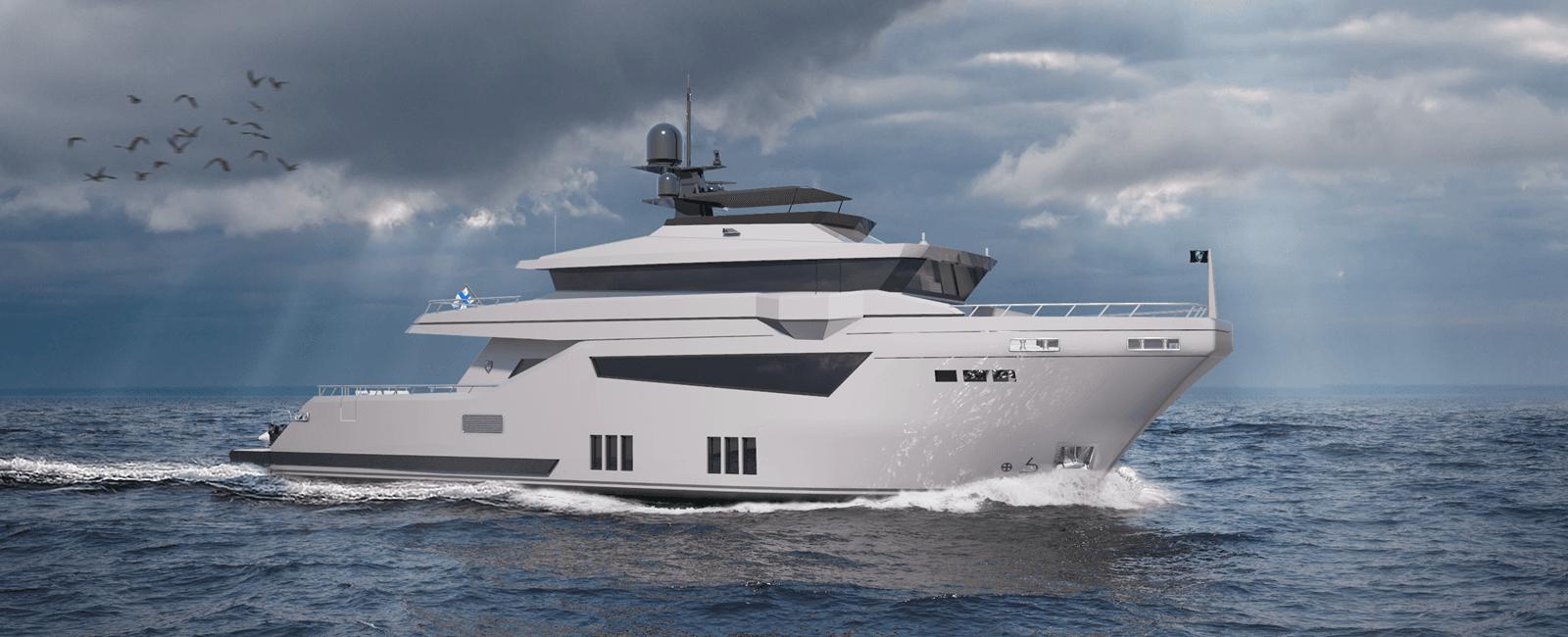

Brizo Yachts

English

Country of Origin

Finland. Brizo Yachts is a Finnish boatbuilder known for its Nordic approach to design and construction, with a strong emphasis on seaworthiness, function, and craftsmanship suited to Baltic conditions.

Manufacturing Locations

Brizo Yachts builds its boats in Finland on the country’s southern coast (Uusimaa region). The company operates an in-house yard where the core production disciplines—aluminum hull fabrication, welding, carpentry, systems installation, and final commissioning—are integrated under one roof. The yard focuses on marine-grade aluminum construction throughout, using proven Northern European supply chains for engines, navigation electronics, glazing, heating, and premium interior materials.

Aluminum work is a particular specialty: hulls and superstructures are welded from high-grade marine alloys with careful attention to material thickness, structural framing, and heat control during welding to ensure strength and dimensional stability. The yard’s workflow typically includes:

- Precision cutting and forming of plates and profiles for hull and deck modules

- MIG welding by experienced specialists in clean, controlled bays

- Dry-fitting of bulkheads and interiors to guarantee alignment and service access

- Full systems integration (engines/outboards, fuel, hydraulic and electrical) with a focus on redundancy and ease of maintenance

- Detailed joinery and upholstery crafted to owner specification, often combining Scandinavian woods with durable, weather-resistant finishes

- Shore-based testing followed by extensive sea trials in local waters to verify performance, noise/vibration levels, and ergonomics

Because the Baltic presents cold winters, short steep seas, and rapidly shifting weather, Brizo Yachts equips its builds accordingly. Features commonly specified by clients include heated cabins, high-visibility glazing, robust deck hardware, safe walk-around layouts, and protection from spray and icing. This real-world testing environment is a hallmark of Finnish boatbuilding and underpins Brizo’s production methods.

The yard also collaborates with local and regional partners for specialist tasks (e.g., advanced coatings, custom glazing, or bespoke metalwork) while keeping design coordination and quality assurance centralized. This approach preserves flexibility for one-off and semi-custom projects, which is central to the brand’s identity.

Reputation and Quality

Brizo Yachts has earned a reputation in Northern Europe for high-quality, custom aluminum boats—ranging from premium dayboats and cabin cruisers to chase boats and superyacht tenders. The brand’s work is frequently noted for:

- Robust aluminum hulls optimized for Baltic conditions, delivering confident handling, dry running, and predictable behavior in chop

- Bespoke layouts and detailing, tailored to owner use-cases from fast commuting and weekend cruising to VIP tender service

- Clean Scandinavian aesthetics inside and out: purposeful lines, ergonomic helm stations, and interiors combining warmth and durability

- Thoughtful systems engineering with service access in mind—important for year-round operation and for tenders that must perform reliably on superyacht programs

- Strong corrosion protection practices, careful isolation of dissimilar metals, and an emphasis on long-life finishes suited to saltwater use

- Quiet, rattle-free structure thanks to rigid aluminum frameworks and well-executed insulation and noise-damping treatments

The brand’s portfolio includes highly customized builds in the 30–60 ft class (and beyond), with power options typically spanning high-output outboards or inboard diesel installations, depending on mission profile. For superyacht clients, Brizo Yachts has become a capable partner for limousine and open tenders that must combine speed, range, guest comfort, and a refined fit-and-finish with practical serviceability. Deck hardware, boarding arrangements, and fendering are often adapted to mothership parameters, illustrating the yard’s agility.

Safety and compliance are core expectations in the Finnish market, and Brizo Yachts builds to applicable European standards (including CE marking) with diligent documentation and sea-trial validation. The strength-to-weight benefits of aluminum enable fuel-efficient performance for a given size and payload; aluminum is also fully recyclable, which aligns with Scandinavian sustainability priorities.

Owners typically highlight:

- The “solid” feel underway, particularly in confused seas

- Low creak/vibration levels for an aluminum platform, a testament to structural design and fit-out quality

- Real-world practicality: easy deck movement, protected seating, and sensible storage; heating/ventilation appropriate for shoulder-season and winter usage

- Tailored electronics suites and helm ergonomics for both owner-operators and professional crews

Brizo Yachts’ role within Finland’s wider maritime cluster is also a strength. Southern Finland hosts a concentration of specialist suppliers, naval architects, and marine engineers. That ecosystem supports rapid prototyping, customization, and reliable after-sales service—key to the yard’s delivery of unique builds and support over the vessel’s life.

In press and word-of-mouth within the Nordic boating community, Brizo Yachts is positioned as a boutique, craftsman-led builder: not a high-volume brand, but one capable of delivering distinctive, tough, and refined aluminum boats for discerning clients. For superyacht programs, captains and managers value the yard’s openness to collaboration on custom features, while private owners appreciate the combination of performance, Nordic practicality, and premium detailing.

Español

País de Origen

Finlandia. Brizo Yachts es un astillero finlandés reconocido por su enfoque nórdico en el diseño y la construcción, priorizando la navegabilidad, la funcionalidad y la artesanía adecuadas para las condiciones del Báltico.

Ubicaciones de Fabricación

Brizo Yachts construye sus embarcaciones en Finlandia, en la costa sur (región de Uusimaa). El astillero integra la fabricación de cascos de aluminio, la soldadura, la carpintería, la instalación de sistemas y la puesta en marcha final en un mismo lugar. Se emplean aleaciones marinas de aluminio y cadenas de suministro nórdicas para motores, electrónica de navegación, acristalamientos, calefacción y materiales interiores de alta gama.

La producción se centra en:

- Corte, conformado y ensamblaje precisos de módulos de casco y cubierta

- Soldadura MIG en talleres limpios con control térmico para asegurar resistencia y estabilidad dimensional

- Preajustes en seco de mamparos e interiores para garantizar tolerancias y acceso al servicio

- Integración completa de sistemas (propulsión, combustible, hidráulica, eléctrica) con enfoque en redundancia y mantenimiento sencillo

- Ebanistería y tapicería a medida, combinando maderas escandinavas y acabados durables

- Pruebas en muelle y navegación de mar en aguas locales para verificar prestaciones, ruidos/vibraciones y ergonomía

El clima del Báltico exige cabinas calefactadas, visibilidad elevada, herrajes robustos y cubiertas seguras. Estas realidades operativas han moldeado la cultura constructiva de Brizo Yachts. Para trabajos especializados (pinturas avanzadas, vidrio a medida, metal mecánica), el astillero recurre a socios regionales, manteniendo el control de diseño y calidad internamente. Este modelo favorece los proyectos “one-off” y semipersonalizados que caracterizan a la marca.

Reputación y Calidad

Brizo Yachts goza de una reputación sólida en el norte de Europa por sus embarcaciones de aluminio personalizadas: dayboats y cabin cruisers de alta gama, chase boats y tenders para superyates. Son habituales:

- Cascos robustos y eficientes para mares cortos y fríos del Báltico

- Distribuciones y detalles hechos a medida según el uso previsto (commuting rápido, crucero de fin de semana, servicio VIP)

- Estética escandinava: líneas limpias, puestos de gobierno ergonómicos e interiores acogedores

- Ingeniería de sistemas con acceso al servicio y fiabilidad para operación todo el año

- Protección anticorrosiva, aislamiento de metales disímiles y acabados de larga duración

- Estructura silenciosa con buen control de vibraciones y aislamiento

El portafolio abarca esloras típicas entre 30–60 pies, con opciones de alta potencia fuera borda o diésel intraborda. En el ámbito de superyates, el astillero destaca por tenders personalizados (limusina y abiertos) que combinan velocidad, autonomía, confort de invitados y acabados refinados con facilidad de mantenimiento.

La construcción según estándares europeos (marcado CE) y unas pruebas de mar exigentes respaldan la seguridad y conformidad. El aluminio aporta ventajas de relación resistencia-peso, eficiencia en combustible y reciclabilidad. Propietarios y tripulaciones resaltan la sensación de solidez, la baja rumorosidad y la practicidad real: circulación segura, asientos protegidos, estiba sensata y climatización adecuada para temporadas frías. La proximidad a proveedores y talento naval en el sur de Finlandia permite prototipado ágil, personalización y soporte posventa confiable, reforzando la propuesta de valor de Brizo Yachts como constructor boutique de alta calidad.

Français

Pays d’Origine

Finlande. Brizo Yachts est un chantier finlandais dont l’approche nordique privilégie la navigabilité, la fonctionnalité et l’artisanat adaptés aux conditions de la mer Baltique.

Sites de Production

La construction s’effectue en Finlande, sur la côte sud (région d’Uusimaa). Le chantier maîtrise en interne la fabrication de coques en aluminium, la soudure, l’aménagement, l’intégration des systèmes et la mise en service. Il utilise des alliages marins d’aluminium et s’appuie sur des fournisseurs nord-européens pour la motorisation, l’électronique, les vitrages, le chauffage et les matériaux intérieurs.

Les points clés du process comprennent:

- Découpe/formage précis de tôles et profils; assemblage par modules

- Soudure MIG en ateliers contrôlés pour assurer rigidité et stabilité

- Pré-montage des cloisons et intérieurs pour vérifier les tolérances et l’accessibilité

- Intégration complète des systèmes avec recherche de redondance et de maintenance aisée

- Menuiserie de qualité, finitions résistantes et personnalisées

- Essais à quai puis en mer dans les eaux locales pour valider performance et ergonomie

Le chantier conçoit des bateaux prêts à affronter un climat rigoureux: cabines chauffées, grande visibilité, ponts sécurisés et accastillage dimensionné. Il collabore avec un réseau régional pour certains métiers spécialisés tout en conservant la coordination et l’assurance qualité, ce qui favorise les projets sur-mesure.

Réputation et Qualité

Brizo Yachts est apprécié pour ses bateaux en aluminium personnalisés: dayboats premium, cabin cruisers, chase boats et tenders de superyachts. Les atouts régulièrement cités sont:

- Coques robustes et marines, performantes dans la mer courte du Baltique

- Aménagements et finitions sur-mesure selon l’usage visé (navette rapide, croisière, tender VIP)

- Esthétique scandinave épurée et postes de pilotage ergonomiques

- Architecture systèmes pensée pour l’entretien et l’exploitation toute l’année

- Protection anticorrosion, isolation galvanique et finitions durables

- Faible bruit et vibrations grâce à une structure rigide et un bon traitement acoustique

Les unités se situent couramment entre 30 et 60 pieds, motorisées en hors-bord puissants ou diesel inboard. Pour les superyachts, le chantier propose des tenders limousines et ouverts combinant vitesse, autonomie, confort passager et finitions haut de gamme avec une grande facilité de maintenance. Les constructions respectent les normes européennes (marquage CE), avec des essais en mer exigeants. L’aluminium procure efficacité, longévité et recyclabilité, en phase avec la sensibilité environnementale scandinave. Dans l’écosystème maritime finlandais, Brizo Yachts se positionne comme un constructeur boutique, flexible et focalisé sur la qualité, apprécié des propriétaires et des équipages pour la fiabilité et la personnalisation poussée.

Русский

Страна происхождения

Финляндия. Brizo Yachts — финская верфь, воплощающая североевропейский подход: мореходность, функциональность и ремесленное качество, рассчитанные на условия Балтики.

Производственные площадки

Строительство ведется в Финляндии, на южном побережье (регион Уусимаа). На верфи объединены ключевые процессы: изготовление и сварка алюминиевых корпусов, столярные работы, монтаж систем и сдача судна «под ключ». Применяются морские алюминиевые сплавы; используются надежные североевропейские поставщики двигателей, электроники, остекления, отопления и интерьерных материалов.

Производственный цикл включает:

- Точный раскрой и гибку листов/профилей, модульную сборку

- Сварку MIG с контролем тепловложения для прочности и геометрии

- «Сухую» сборку переборок и интерьеров для проверки допусков и сервисного доступа

- Полную интеграцию топливных, гидравлических и электросистем с упором на отказоустойчивость

- Индивидуальную отделку и обшивку, сочетающую скандинавские породы древесины и износостойкие покрытия

- Швартовые испытания и ходовые испытания в местных водах для валидации характеристик и эргономики

Суровые балтийские реалии диктуют закрытые и отапливаемые рубки, высокий обзор, безопасные палубы и мощное оборудование. Brizo Yachts сохраняет координацию проектирования и контроля качества на своей площадке, привлекая региональных подрядчиков для узких задач, что оптимально для уникальных и полу-кастомных проектов.

Репутация и качество

Brizo Yachts известна индивидуальными алюминиевыми лодками: премиальные дневные катера и каютные крейсера, «чейз-боты», а также тендеры для суперъяхт. Отличительные черты:

- Прочные и «сухие» корпуса, уверенно работающие в короткой волне

- Планировки и детали под конкретные сценарии эксплуатации (быстрые переходы, выходные, VIP-трансфер)

- Скандинавская эстетика, эргономичные посты управления, теплые и износостойкие интерьеры

- Вдумчивое проектирование систем с учетом круглогодичной эксплуатации и удобства обслуживания

- Серьезная антикоррозионная защита и гальваническая изоляция

- Низкий уровень шумов/вибраций благодаря жесткой силовой схеме и качественной изоляции

Типичные размеры — 30–60 футов, с мощными подвесными или дизельными стационарными двигателями. В сегменте суперъяхт верфь строит лимузин-тендеры и открытые тендеры, сочетающие скорость, дальность, комфорт гостей и высокую культуру отделки. Строительство ведется в соответствии с европейскими нормами (CE), с тщательными ходовыми испытаниями. Алюминий обеспечивает выгодное соотношение прочности и массы, топливную эффективность и полную переработку. В морском кластере Финляндии Brizo Yachts воспринимается как «бутик»-строитель с гибкой кастомизацией и высоким качеством, что ценят как владельцы, так и профессиональные экипажи.

中文

原产国

芬兰。Brizo Yachts 是一家芬兰船厂,延续北欧设计与制造传统,强调适航性、功能性与工艺,适配波罗的海的海况与气候。

生产地点

Brizo Yachts 在芬兰南部海岸(乌西马地区)设有自有船厂,核心工序在厂内完成:海洋级铝合金船体与上层建筑的制造与焊接、木作内装、系统集成及交付调试。发动机、航电、玻璃、加热及高端内饰材料等主要部件优选北欧供应链。

关键流程包括:

- 板材/型材的精密切割、成形与模块化装配

- 受控环境下的 MIG 焊接,重视热输入与变形控制,确保强度与尺寸稳定

- 隔舱与内装的干装校核,保证公差与后期维护空间

- 推进、燃油、液压、电气等系统的完整集成,强调冗余与易维护

- 斯堪的纳维亚风格的木作与软装,兼顾质感与耐候性

- 岸试与海试验证性能、噪振与人机工程

考虑到严寒与短陡浪等海况,船型常配备加热舱室、大面积高通透玻璃、安全的行走甲板与坚固的甲板设备。对于特殊工艺(如高级涂装、定制玻璃、精密金属件),船厂与区域内伙伴合作,但将设计协调与质量管控掌握在内部,适合一船一方案与半定制项目。

声誉与质量

Brizo Yachts 在北欧以定制化铝合金船著称,涵盖高端日间艇、带舱巡航艇、追逐艇,以及超级游艇的礼宾/接载艇。其产品通常具备:

- 适应波罗的海的强壮船体与良好航行性,干爽、稳定且可预期

- 围绕实际用途量身定制的布局与细节(快速通勤、周末巡航、VIP 接送)

- 北欧极简美学与人体工程优化的驾驶舱

- 以全年运营为目标的系统工程,强调可靠性与维护便捷性

- 严格的防腐蚀与异种金属隔离策略以及耐久外饰

- 通过刚性结构与隔振降噪实现的低噪声、低振动体验

典型尺寸集中在 30–60 英尺区间,可根据任务选择大功率舷外机或船内柴油配置。面向超级游艇,Brizo Yachts 提供豪华“礼宾舱顶”与开放式接载艇,兼顾速度、续航、宾客舒适度与高端装饰,并在维护性上满足母船运营需求。船厂遵循欧洲法规(含 CE 标识)进行设计与建造,并以严格海试保障安全与性能。铝材具备优良的强度重量比、燃油效率与可循环性,符合北欧对可持续性的重视。

依托芬兰南部发达的海事产业生态(设计、工程、供应链与售后),Brizo Yachts 能快速原型迭代、深度定制并提供可靠的生命周期支持。市场普遍将其视为精品型、工艺驱动的铝船制造商:规模不求庞大,但在独特性、坚固性与精致度之间把握到位,受到私人船东与专业船队的认可。

Main Competitors

Brizo Yachts operates in a niche where rugged Northern European design, aluminum construction, and high-end customization intersect. As a result, its competitive set spans three overlapping arenas: Scandinavian aluminum boatbuilders (performance/leisure and professional-leaning craft), Nordic commuter/pilothouse brands in composite that target similar use cases, and international superyacht-tender specialists serving the custom limousine/open tender segment. The following landscape outlines the principal competitors that buyers most frequently cross-shop against Brizo’s offerings.

-

Anytec (Sweden). Anytec is a benchmark name in Scandinavian aluminum sport boats, prized for high-speed capability, crisp handling, and minimalist Nordic styling. Models are typically production-series with well-honed hulls built for the short, steep seas common in the Baltic and the Scandinavian archipelagos. Compared with Brizo’s bespoke/semi-custom approach, Anytec generally delivers a more standardized product at higher volume; buyers who want a “turnkey” aluminum performance boat with proven ergonomics often consider Anytec, while those seeking one-off layouts, custom systems integration, or superyacht-specific fit-out lean toward Brizo.

-

XO Boats (Finland). XO blends aluminum hulls with composite superstructures and is known for aggressive, modern design that appeals to performance-minded owners who also want practical, all-weather capability. XO’s model families (e.g., DFNDR/Explorer lines) compete with the use-cases Brizo targets—fast commuting, weekend cruising in demanding waters, and multipurpose utility. XO’s manufacturing is more series-oriented than Brizo’s craft-level customization. For a buyer, the decision often hinges on whether standardized layouts and economies of scale are preferred over Brizo’s deep customization and superyacht program flexibility.

-

Marell Boats (Sweden). Marell is recognized for fast, seaworthy aluminum platforms that bridge leisure and professional segments (law enforcement, patrol, chase boats). Their boats are engineered for reliability and high-speed stability, which makes them compelling alternatives for owners prioritizing performance and robust build quality. Brizo typically distinguishes itself with higher degrees of interior tailoring and luxury detailing—especially for tender and VIP missions—while Marell commands attention for advanced hull forms and operational durability.

-

Alukin (Sweden). Alukin offers a broad lineup of aluminum boats with a reputation for tough construction, functional layouts, and Scandinavian practicality. Alukin’s focus tends to be rugged family/utility dayboats and cabin boats that thrive in northern climates. In cross-shopping, Alukin competes on the same core value proposition—strength, longevity, and low-maintenance aluminum—while Brizo often positions as the more bespoke, finer-finished alternative for clients seeking a higher level of customization and superyacht-compatible detailing.

-

Buster Boats (Finland). Buster is one of the largest aluminum boat brands in Europe, with a comprehensive range covering everything from small utility craft to larger family boats. Backed by strong industrial processes and widespread dealer support, Buster offers proven reliability and residual value. Although Buster competes on the material (aluminum) and Nordic usability, Brizo differentiates through low-volume craftsmanship, tailored interiors, and project-by-project engineering—key for owners who need custom layouts, specialized systems, or unique finish levels.

-

Husky by Finnmaster (Finland). The Husky line leverages aluminum hull construction under the Finnmaster umbrella, combining practicality with user-friendly design and a broad dealer network. It addresses similar climates and use patterns. Compared to Brizo’s semi-custom ethos, Husky is more standardized, appealing to owners who want predictable lead times and mainstream configurations rather than bespoke solutions.

-

Targa by Botnia Marin (Finland). Although built in composite rather than aluminum, Targa is a direct competitor on mission profile: deeply capable commuter and “go-anywhere” pilothouse boats engineered for year-round use in demanding seas. Targa’s reputation for serious offshore ability, outstanding pilothouse ergonomics, and long service life makes it a frequent consideration for the same buyer cohort. Clients choosing Brizo over Targa typically do so for the metal-boat benefits (impact resistance, repairability, custom structural solutions) and the elevated scope for custom interiors and fittings.

-

Sargo (Finland). Another composite (GRP) stalwart in the rugged Nordic commuter segment, Sargo delivers strongly built, all-weather family cruisers with balanced performance and comfort. Like Targa, Sargo overlaps Brizo on use-case—year-round practicality, protected decks, safe walkaround ergonomics—while differing in hull material and series-production philosophy. Buyers often weigh the tactile and structural attributes of aluminum and the custom freedom Brizo offers against Sargo’s mature model range and series efficiencies.

-

Nord Star (Finland). Nord Star’s wheelhouse cruisers are known for robust construction, sensible deck planning, and confident handling in northern latitudes. As with Targa and Sargo, material is the primary divergence with Brizo; however, in terms of operational mission—short-notice trips in mixed weather, family or professional usage, and the desire for a secure pilothouse—there is meaningful cross-shopping. Brizo’s aluminum-first construction and bespoke fit-outs appeal to owners who prize personalization and metal-boat maintenance logic.

-

Pascoe International (UK). In the superyacht world, Pascoe is a key tender competitor, known for premium limousine and open tenders that emphasize luxury, guest comfort, and integration with mothership operations. This is one of the most relevant comparisons for Brizo in the custom tender niche. Pascoe’s deep tender-specific design and service infrastructure is formidable; Brizo competes with a Nordic aluminum proposition—robustness, custom engineering, and the ability to tailor to exacting operational briefs.

-

Compass Tenders (UK). Another heavyweight in the custom superyacht tender market, Compass is renowned for one-off limousine and open designs with immaculate detailing and mothership-matching aesthetics. Compass, like Pascoe, provides stiff competition on bespoke capabilities. Brizo’s differentiator is its metal-boat expertise and Baltic-tested engineering, which can be decisive for programs prioritizing ruggedization and easy service access while still expecting high-end finishing.

-

Yachtwerft Meyer (Germany). Specializes in custom tenders for megayachts, including innovative launch/retrieval solutions, carbon structures, and complex systems integration. Yachtwerft Meyer is a reference competitor where engineering sophistication and exacting build standards are paramount. Brizo counters with deep aluminum know-how, cold-climate practicality, and personalized owner/captain collaboration in design and outfitting.

-

Hodgdon Tenders (USA). From a storied Maine shipyard heritage, Hodgdon Tenders produces high-end custom limousine and open tenders for superyachts, often featuring composite craftsmanship and luxury interiors. In tender competitions, Hodgdon stands out for finishing and brand recognition. Brizo’s pitch focuses on robust Scandinavian metalwork, customizability, and the operational resilience expected in harsher climates.

-

Cockwells (UK). Known for bespoke tenders and modern classic launches in composite/wood, Cockwells competes on craftsmanship and customization. Brizo competes by offering similarly bespoke solutions grounded in aluminum, a different aesthetic and structural proposition that appeals to owners who value the material’s serviceability and durability.

-

Vikal (Australia). A highly respected tender specialist with a portfolio of custom builds for some of the world’s largest yachts. In head-to-head tender bids, the choice often comes down to the mothership’s aesthetic requirements, preferred materials, and service network alignment. Brizo’s north-European base and aluminum specialization provide a distinctive alternative for programs operating in the Atlantic/Northern Europe theaters.

-

Wajer (Netherlands). Though Wajer’s boats are composite and positioned as luxury dayboats, they often serve as superyacht chase boats and high-profile owner tenders. Their brand strength, refinement, and performance are compelling to many of the same clients. Brizo’s countermove is bespoke metal construction and the ability to configure highly specific workboat-grade details with a luxury finish, which some programs prioritize over a standardized premium dayboat.

-

Windy (Norway, with production in Poland). Windy’s high-quality performance cruisers and chase boats regularly appear on superyachts as fast, guest-friendly platforms. The overlap with Brizo comes in the chase-boat role and the expectation for reliability and seakeeping; material and customization depth are the key differentiators.

Taken as a whole, Brizo Yachts competes best where owners or captains want an aluminum platform customized around a defined mission profile. Against series-production Nordic brands, Brizo brings deeper tailoring and superyacht program thinking. Against tender specialists, Brizo delivers a distinctly Nordic metal-boat solution with operational ruggedness and straightforward serviceability while still offering refined finishing and guest-forward detailing.

Current Production Status

Production is ongoing. Brizo Yachts continues to build low-volume, semi-custom and custom aluminum boats in Finland, with a project cadence typical of boutique Northern European yards focused on engineering-led craftsmanship rather than mass production. The yard’s operating model revolves around taking a client brief—private owners, professional operators, or superyacht programs—and translating it into a hull, deck, and interior specification that is optimized for a defined mission: fast commuting in exposed waters, family weekending across seasons, chase-boat duties, or VIP tender service to a mothership.

Aluminum is central to Brizo’s production identity. Benefits include impact resistance, predictable deformation behavior, straightforward repairability, and excellent strength-to-weight ratios when engineered properly. The yard’s process emphasizes precise plate cutting and forming, controlled MIG welding practices (with strong attention to heat-input management to preserve material properties and geometry), and structural detailing that minimizes vibration and noise transmission. These metalwork fundamentals are paired with Scandinavian interior joinery—often warm woods and durable finishes—that balance a clean, contemporary aesthetic with the practical requirements of cold, wet climates.

Systems integration is handled with a strong emphasis on service access and redundancy. Clients typically specify modern navigation suites, thermal and anti-icing provisions for shoulder-season use, and deck hardware scaled for northern seas. For superyacht tenders and chase boats, Brizo coordinates closely with the mothership’s team to align boarding geometry, fendering strategy, lifting points, cradle interfaces, and stowage constraints. The yard’s flexibility in tailoring engine choices (high-output outboards or inboard diesels), fuel capacity, and auxiliary systems allows each build to be tuned for speed, range, and payload in a way that suits the operating profile.

Compliance and validation are integral to the production status. Brizo builds to applicable European standards (including CE marking), and its coastal Finnish location provides ready access to real-world sea trial conditions that stress-test hull behavior, ergonomics, water management on deck, and noise/vibration levels. The result is a feedback loop—yard to sea and back to yard—that informs incremental refinements across projects, even when those projects are one-off or semi-custom.

Because the company operates as a boutique yard, schedules are organized around a finite number of concurrent builds rather than mass throughput. Owners should expect collaborative design iterations, technical reviews on structure and systems, and mock-ups or dry-fit checks to validate spatial planning before final installation. This approach, while more time-intensive than series production, is what enables Brizo to deliver boats that feel purpose-built—an important differentiator for demanding northern cruising or the exacting day-to-day needs of a superyacht support fleet.

After-delivery support is another element of the active production/operations picture. Brizo’s specialization in aluminum and its partnerships with regional suppliers make it straightforward to handle upgrades, seasonal adjustments, or operational tweaks gleaned from early months of service. In superyacht contexts, the yard’s willingness to collaborate with captains, engineers, and yacht managers is especially valuable; it shortens the feedback loop and helps ensure the tender remains aligned with mothership schedules and guest-service expectations.

In summary, Brizo Yachts is actively building and delivering custom and semi-custom aluminum boats, with a production rhythm that prioritizes craftsmanship, engineering rigor, and practical, year-round usability. Clients who require individualized solutions—whether for northern family cruising or for superyacht tender programs—will find the yard’s ongoing operations tailored to meet those exact needs.

Frequently Asked Questions

Question:What type of boats does Brizo Yachts primarily build?

Answer:Brizo Yachts focuses on custom and semi-custom aluminum boats designed for demanding, all-weather use. Typical projects include premium dayboats, pilothouse/commuter boats, chase boats, and superyacht tenders (both open and limousine configurations). The common denominator is robust marine-grade aluminum construction paired with Scandinavian ergonomics and finish.

Question:Why aluminum, and what alloys are typically used?

Answer:Aluminum offers an excellent strength-to-weight ratio, impact resistance, and straightforward repairability, making it ideal for northern waters and professional-grade operation. Marine-grade alloys commonly used in this segment include high-magnesium 5xxx-series plates for hulls and superstructures, which are optimized for corrosion resistance in saltwater when correctly isolated and protected.

Question:How does the yard address corrosion protection in aluminum boats?

Answer:Effective corrosion management in aluminum boats relies on material selection, isolation of dissimilar metals, protective coatings, and sacrificial anodes. Builds in this category typically use: carefully specified bonding/grounding plans; non-conductive gaskets and bushings at hardware penetrations; epoxy primers and marine coatings where appropriate; and properly sized anodes matched to the operating environment (salt, brackish, or freshwater). Routine inspection and timely anode replacement are part of standard maintenance.

Question:Are the builds standardized or fully bespoke?

Answer:The ethos is low-volume, high-customization. Many projects start from proven platforms—hulls and deck plans refined for Baltic-style conditions—and are then tailored to the owner’s mission (e.g., fast commuting, family weekending, or superyacht tender duties). Interior layouts, systems packages, deck hardware, and lifting arrangements are commonly customized.

Question:What kind of sea conditions are these boats designed for?

Answer:Hulls are engineered for short, steep seas common to the Baltic and other northern waters, with an emphasis on predictable handling, dry running, and structural robustness. Enclosed wheelhouses or raised pilothouses with extensive glazing and heating/defogging systems support year-round usability.

Question:Which engine configurations are typical?

Answer:Both high-output outboards and inboard diesels are used, selected according to mission profile. Outboards suit high-speed chase and tender roles with simpler service access; inboards (shaft or sterndrive) can favor range, weight distribution, and quieter running. Single, twin, or triple installations are common depending on size and required performance.

Question:What speeds can be expected?

Answer:Performance depends on length, displacement, and power. As a general guide in this class: well-powered 30–40 ft aluminum boats often cruise in the mid-20s to mid-30s knots and can top out from the high-30s to 50+ knots with appropriate power. Larger 45–60 ft builds commonly cruise in the mid-20s to low-30s knots with top speeds in the 35–45 knot band, depending on setup.

Question:How is noise and vibration handled in aluminum boats?

Answer:Structural design, panel stiffness, strategic insulation, and resilient mounting of machinery and interiors are key. Modern aluminum builds integrate sound-dampening materials in bulkheads/linings and isolate vibration sources to achieve a quiet ride comparable to premium composite platforms.

Question:What about heating, ventilation, and comfort in cold climates?

Answer:Cold-weather operation is a core design driver. Typical options include diesel or hydronic heating, heated demisters, insulated glazing, and well-sealed doors/hatches. Ventilation solutions—such as roof hatches, sliding windows, and forced-air systems—are configured for both winter dryness and summer comfort.

Question:Are the boats compliant with European recreational standards?

Answer:Builds in this category are produced to applicable European requirements, including CE marking. The specific design category (e.g., B Offshore or A Ocean) depends on size, hull design, freeboard, stability, and other engineering parameters defined per project.

Question:What customization is available for superyacht tenders?

Answer:Superyacht tender projects often include bespoke boarding solutions, fendering tailored to the mothership, custom seating for guest transfers, limousine cabins with climate control, and precise lifting arrangements compatible with onboard cranes or davits. Electrical systems and charging, fuel interfaces, and storage cradles are designed to integrate seamlessly with the mothership.

Question:Can the builder coordinate with third-party naval architects or designers?

Answer:Collaboration is common in this niche. Depending on the project, internal engineering is complemented by external specialists for styling, structural optimization, or specific systems. The goal is to align aesthetics, performance, and operational requirements without compromising serviceability.

Question:What materials and finishes are typical for interiors?

Answer:Scandinavian woods, hard-wearing deck coverings, marine textiles, and corrosion-safe fittings are standard. Interior treatments focus on warmth, light, durability, and easy maintenance. Owners can specify bespoke veneers, upholstery, and lighting packages to achieve either minimalist Nordic style or a more luxurious superyacht feel.

Question:Is there provision for year-round operation and icing conditions?

Answer:Yes. Northern operation often entails heated wheelhouses, high-visibility glazing, purposeful drainage and water management on decks, aggressive nonslip surfaces, and carefully positioned handholds. Electrical and hydraulic systems are installed with cold-weather reliability in mind, and optional thermal management can be extended to lockers or critical spaces.

Question:How are electrical and navigation systems integrated?

Answer:Modern boats in this segment use networked marine electronics, integrating chartplotters, radar, sonar, cameras, and thermal imaging as required. Electrical architectures are designed with clear labelling, access panels, and schematics for efficient diagnostics. Redundancy is common for mission-critical functions on professional or tender builds.

Question:What is the typical fuel capacity and range?

Answer:Capacities vary by hull size and mission. As a broad indication: 30–35 ft builds might carry several hundred liters for day-range use; 36–45 ft commuter or chase boats often carry mid-hundreds to low four figures (liters) for multi-day autonomy; 50–60 ft projects may be specified with four-figure capacities for extended legs. Range is a function of power, speed, and load, and is tuned during specification.

Question:How are lifting points and structural inserts managed for tenders?

Answer:Lift points, pad eyes, and reinforcement are engineered into the structure from the outset to handle dynamic loads. The alignment with slings, spreaders, or dedicated lifting frames is validated through calculation and sea-trial checks. Deck interfaces and chock geometry are developed in parallel to ensure safe launch/recovery.

Question:What does the sea-trial process look like?

Answer:Sea trials verify hull performance, steering and trim behavior, noise/vibration levels, water management on deck, and functionality of all systems. Trials are conducted in conditions representative of real use, allowing final adjustments to propellers, engine calibration, and helm ergonomics before handover.

Question:What maintenance regime is recommended for aluminum boats?

Answer:Annual haul-out, inspection of coatings and anodes, antifouling updates, and checks on electrical bonding are standard. Periodic attention to deck penetrations, sealants, and hardware isolation preserves long-term corrosion resistance. For outboards, scheduled servicing per manufacturer guidelines is essential; for inboards, periodic alignments and fluid/filter changes are routine.

Question:Are repainting and refit straightforward on aluminum hulls?

Answer:Aluminum is refit-friendly when proper surface prep and coating systems are used. Blasting/abrading to the correct profile, applying epoxy primers, and finishing with marine topcoats produce durable results. Structural modifications (e.g., new hardpoints or seating) are feasible with engineering review and compliance checks.

Question:What interior layouts are common on commuter and weekender builds?

Answer:Many 30–40 ft boats feature a forward cabin with a double berth, convertible saloon seating, a compact galley, and an enclosed head. Larger 42–50 ft platforms may add a guest cabin or expanded galley. Superyacht limousine tenders often prioritize seating comfort, climate control, and luggage stowage over overnighting.

Question:Do these boats support cold starts and winter operation?

Answer:Yes. Engine pre-heating options, robust starting batteries, and cold-rated lubricants are commonly specified. Interior heating, demist systems, and moisture control (including dehumidification while moored) support safe and comfortable winter use.

Question:How flexible are the helm and deck ergonomics?

Answer:Helm stations are typically designed with adjustable seating/standing positions, shock-mitigating seats as an option, and optimized sight lines. Decks emphasize safe movement: wide side decks, integrated handrails, and protected seating. Fittings are placed for one-person operation in tight conditions where needed.

Question:Are there sustainable aspects to aluminum construction?

Answer:Aluminum is fully recyclable, and weight-efficient structures translate into favorable fuel economy for a given mission profile. Efficient hull forms, modern engines, and considered systems integration further contribute to reduced consumption over the boat’s life.

Question:What documentation is provided with a custom build?

Answer:A comprehensive owner’s manual, system schematics, wiring diagrams, equipment lists, and compliance documents are standard for boats in this category. For tenders, lifting plans, cradle drawings, and ship-integration notes are typically included.

Question:How do lead times work for custom and semi-custom projects?

Answer:Lead times depend on yard workload, project size, and customization depth. A structured design and engineering phase precedes metalwork and fit-out, with scheduled reviews and approvals to ensure the finished boat aligns with the agreed mission and performance targets.

Question:Can these boats be used as workboats or patrol craft?

Answer:Yes. The same structural and systems approach that benefits private owners and superyacht programs is applicable to professional uses. Layouts and equipment can be adapted for patrol, pilotage, or support roles, emphasizing durability, redundancy, and quick serviceability.

Question:What differentiates these boats from series-production Nordic brands?

Answer:Customization depth, aluminum-first engineering, and superyacht-grade detailing set them apart. While series brands offer excellent standardized layouts and scale efficiencies, the custom/semi-custom approach enables purpose-built solutions for challenging climates and specialized operational demands.

Question:Do the boats support gyro stabilization or advanced ride control?

Answer:Options such as gyrostabilizers, interceptor trim systems, and active tabs can be integrated, subject to weight, space, and power budgets. These systems are specified case-by-case during the design phase.

Question:Are there options for hybrid or alternative propulsion?

Answer:Interest in hybridization is growing. Feasibility depends on the specific hull and mission profile; energy storage, weight distribution, and thermal management must be considered alongside range and speed requirements. Projects pursuing hybrid concepts typically involve additional engineering studies.

Question:What kind of glazing is used?

Answer:Laminated and tempered marine glass with appropriate thermal performance is typical, often with heated demist/defog and wiper systems. Framing is designed to minimize blind spots while maintaining structural integrity and watertightness.

Question:How is safety addressed for offshore operation?

Answer:Safety features include high freeboard, secure coamings, robust handholds, anti-slip decks, self-draining cockpits, and redundant bilge and electrical systems. Navigation and communication packages are tailored to the operating area, with emergency systems specified per owner or commercial requirements.

Available Models

Note on model structure: Brizo Yachts is known for semi-custom and custom aluminum builds rather than a rigid, mass-produced catalog. As such, “models” are best understood as common size classes and mission-oriented configurations. The specifications below are representative examples that owners frequently commission; final dimensions, layouts, speeds, and power packages are tailored per project and may vary.

-

30–35 ft Weekender/Commuter (semi-custom)

- Length overall: approximately 9.5–10.7 m

- Beam: approximately 2.9–3.3 m

- Draft: typically 0.6–0.9 m (configuration-dependent)

- Layout: enclosed wheelhouse with seating for 4–6; forward cabin with double berth; compact galley; enclosed head; extensive storage for foul-weather gear

- Engine type: single or twin outboards, or single inboard diesel (shaft or sterndrive), sized for efficient cruise with reserve for adverse conditions

- Expected performance: cruise typically mid-20s to low-30s knots; top speed from mid-30s to low-40s knots depending on power and load

- Use cases: fast commuting in exposed waters, all-season family boating, support craft for coastal properties

-

36–40 ft Pilothouse/Explorer (semi-custom)

- Length overall: approximately 11.0–12.2 m

- Beam: approximately 3.2–3.7 m

- Draft: typically 0.7–1.0 m

- Layout: raised pilothouse with 360-degree visibility; salon seating convertible to berth; forward owner cabin; optional guest berth or utility/storage space; head with separate shower on larger variants

- Engine type: twin outboards for high speed and service ease; or twin inboard diesels for range and balanced trim

- Expected performance: cruise in the high-20s to mid-30s knots; top speed from high-30s to 45+ knots in performance-focused setups

- Use cases: mixed-weather coastal cruising, island-hopping, professional support roles (pilot/taxi), tender duties for large yachts

-

40–45 ft Chase Boat/Tender (semi-custom)

- Length overall: approximately 12.2–13.7 m

- Beam: approximately 3.5–4.0 m

- Draft: typically 0.8–1.1 m

- Layout: open or cabin variants; shock-mitigating seating for multiple passengers; optional bow or side boarding; reinforced lifting points and chock interfaces; configurable fendering for yacht-side operations

- Engine type: twin or triple outboards; twin inboard diesels for alternative weight distribution and endurance

- Expected performance: sustained fast cruise in the 30–35 knot range; top speeds in the low-40s to 50 knots with appropriate power and weight control

- Use cases: superyacht chase/tender, support for watersports and guest transfer, rapid logistics in archipelagos

-

40–45 ft Limousine Tender (custom)

- Length overall: approximately 12.2–13.7 m

- Beam: approximately 3.5–4.0 m

- Draft: typically 0.8–1.1 m

- Layout: enclosed limousine cabin with climate control; seating for 8–12 depending on layout; luggage stowage; dedicated crew helm station; custom boarding geometry to suit mothership

- Engine type: twin outboards or twin inboard diesels; noise and vibration attenuation prioritized

- Expected performance: cruise in the mid-20s to low-30s knots; top speeds typically in the mid-30s to low-40s knots, prioritized for guest comfort and seakeeping rather than peak speed

- Use cases: VIP guest transfer, tender-to-shore operations in varied sea states, marina-to-mothership shuttle

-

46–52 ft All-Weather Commuter/Weekend Cruiser (semi-custom)

- Length overall: approximately 14.0–15.8 m

- Beam: approximately 4.0–4.6 m

- Draft: typically 0.9–1.2 m

- Layout: large pilothouse/salon; 2-cabin arrangement (owner’s forward plus guest amidships) with 1–2 heads; galley-up or galley-down by owner choice; robust deck hardware; walkaround side decks

- Engine type: twin inboard diesels (shafts or sterndrives) for efficient mid-range cruise; outboards possible on performance-oriented versions if specified

- Expected performance: cruise typically mid-20s to low-30s knots; top speeds from mid-30s to low-40s knots depending on displacement and power

- Use cases: extended coastal cruising across seasons, family expeditions in colder climates, professional transport in challenging conditions

-

50–65 ft Aluminum Sport Yacht/Expedition Dayboat (custom)

- Length overall: approximately 15.2–19.8 m

- Beam: approximately 4.5–5.4 m

- Draft: typically 1.0–1.4 m

- Layout: multiple custom cabin options (2–3 cabins typical); expanded galley; salon focused on sightlines and social space; optional crew berth for tender operations; heavy-duty deck gear for adventure equipment

- Engine type: twin inboard diesels (shafts) with options for auxiliary systems (stabilization, hotel loads); performance tuning to balance range with speed

- Expected performance: cruise in the mid-20s to low-30s knots; top speeds from mid-30s to low-40s knots depending on displacement and specification

- Use cases: high-latitude day expeditions, long-weekend cruising with challenging passages, large-yacht support operations where payload and customization are key

-

Professional and Utility Variants (custom)

- Length overall: typically 9–15 m

- Beam and draft: mission-specific

- Layout: configurable work decks, protective cabins, reinforced towing and rescue points, specialty electronics (thermal cameras, AIS, loudhailers)

- Engine type: commercial-rated outboards or inboard diesels with redundancy and extended service intervals

- Expected performance: tuned to duty cycle; emphasis on reliability and handling under load

- Use cases: patrol, pilot transfer, crew movement, logistics in rough conditions

Key characteristics across the semi-custom portfolio:

- Structure: welded marine-grade aluminum hulls and superstructures, engineered for stiffness and long-term durability

- Systems: clean electrical architecture with accessible routing, sensible service access to machinery, and standardized componentry where beneficial

- Comfort: thermal and acoustic insulation, effective climate control, glare-resistant glazing, ergonomic helms suitable for seated or standing control

- Safety: secure coamings and handholds, high-traction decks, self-bailing cockpits, redundant bilge and power systems, and navigation packages tailored to northern waters

- Finish: Scandinavian interior design ethos with hard-wearing materials; exterior coatings selected for saltwater durability; fendering and hardware scaled for harsh conditions

Because each project is specified to a brief, owners can prioritize different operational goals. For example:

- A 36–40 ft commuter might trade some top speed for increased fuel capacity and extended shoulder-season heating.

- A 40–45 ft chase boat could optimize for blistering acceleration and guest seating with shock-mitigating seats.

- A 50–65 ft aluminum sport cruiser may emphasize two generous cabins, stabilized comfort at anchor, and range for multi-day adventures.

These examples illustrate the brand’s core philosophy: a proven aluminum platform tailored to exact use cases, with a focus on reliability, service access, and real-world performance in mixed conditions.

Learn more on the “BRIZO YACHTS”

To learn more on the “BRIZO YACHTS” or to get advice on how to buy or sell a yacht or get a great price for a yacht charter

please call +1 (954) 274-4435 USAOnly deal with professionals!